Who we are

ITALIAN CHEMISTRY

Titolchimica is proposed as a partner for your company in all those activities that involve the need to manage chemicals:

- the search for methods of analysis and related reagents;

- the development of solutions for specific uses;

- the need for customised formulations and concentrations,

- the need to differentiate the packaging;

- knowledge of the regulations in force for chemical preparations and products.

Our company makes available its wealth of knowledge and experience gained in 30 years of activity, collaborations and projects carried out with Research Institutions, Universities, Manufacturing Groups, along with a passion for obtaining a "tailor-made" result.

We founded our company in the name of flexibility and service tailored to the customer, intervening with agile and differentiated productions in a scenario that at the time consisted of rigid and cold catalogues of firms that have only now discovered the flexibility of “tailor-made solutions”, several years after our entry into the market.

We have always been committed to ensuring that our tailor-made service rhymes with quality and continuous improvement, which is why we invest primarily in information and training at all levels, which we believe to be at the heart of the development of small companies like ours.

The quality certification according to ISO 9001 is the result of this commitment.

Our production and packaging capacity ranges from 1 ml to over 1000 litres of reagents and specific concentration solutions for various analytical techniques and industrial processes, with the aim of satisfying individual company needs by making available our facility that can solve organisational, environmental, safety as well as economic and time-related problems for customers.

Each product is guaranteed through the reproducibility of the production methods, starting from the definition of specifications agreed with the issue of the relevant certificates of analysis of the batch, with the search and use of recognised standard reference materials.

To all this technical commitment to product quality must be added the constant technical and regulatory updating for data management, for the classification, packaging and labelling of preparations, the issue of the relevant safety data sheets and other activities in compliance with legal obligations for the use of chemical products: from the knowledge of restrictions on use, constraints on drug precursors, to the communication to the archive of dangerous preparations, from tax regulations to the A.D.R. regulations for the transport of dangerous goods, etc.

To complete the service, we also take care of the transport and delivery of your products to your address, with our suitable and authorised vehicles and staff trained in handling them.

Productions:

- N.I.S.T. traceable Standard Solutions;

- Ready-to-use and concentrated titrated solutions in vials;

- pH buffer solutions concentrated and ready for use;

- Conductivity solutions, redox, maintenance solutions for electrodes;

- Standards and reagents for ion-selective electrodes;

- Solutions and Standards for A.A. and ion chromatography;

- Reagents for laboratory chemical analysis;

- Reagents for automatic analysers and process controls;

- European Pharmacopoeia reagents and standards;

- Dyes for microscopy;

- Chemical products for laboratory and industrial use;

- Third party packaging;

- Technical assistance;

- Supplies for chemical analysis laboratories.

Plant and equipment:

- Factory of 1000 m2 on a total area of 6000 m2, completely authorized for the type of activity carried out. Production area served by an acid and basic fume extraction and abatement system

- flow rate of 6000 Nm3/h;

- Activated carbon extraction system for solvents;

- Production area and warehouses covered by a fire-fighting system with smoke-heat detection and water and foam extinguishing for separate rooms REI120;

- System for the production of 700 litres/hour of pure water with grade II reagent : Double stage osmosis + G.E* electrodeionization;

- Stainless steel reactor 1000 litres;

- Various PEHD tanks with stainless steel + PP stirrers of 5000 - 3000- 1000 - 600 litres;

- Stainless steel stirrers with various capacities;

- Agitators - ee transfer pumps + compressed air;

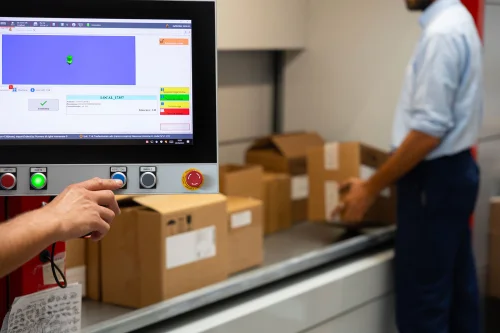

- Computerized dosing and mixing system for critical productions;

- Transfer unit with drag pump for 10-25-50 litres;

- Bottling, capping and labelling line 500-1000 ml;

- Bottling and capping line 100-500-1000 ml;

- Bottling line 100-250-500 ml;

- Bottling, capping and labelling line 10-100 ml;

- Precision bottling lines and closing for 50-200 ml PEHD vials;

- Pressure filtration system up to 0.1 micron.

History

Founded in 1981 in Rovigo, the company was born from the intuition to seize the potential of the laboratory chemical reagent sector.

With a strong passion for chemistry, and the building of a solid entrepreneurial footprint, the company began a path of growth that led it to become a benchmark in the Italian industrial landscape.

During the 1980s and 1990s, the company laid the foundations of the collaborations with customers and suppliers that still exist today and, thanks to its ability to adapt quickly to the needs of customers and the market, it expanded its offerings: from concentrated and ready-to-use titrant and buffer solutions to reagents for automated analyzers, from slide preparation products to microscopy dyes, from NIST traceability of standard solutions to custom productions that also allowed it to go outside the laboratory and tackle different industrial productions.

This innovative approach, together with the formation of a specialized team of in-house operators and skilled employees for each business activity and an appropriate structure, has characterized its growth, market recognition, and consolidated its leadership position.